Wax and structure brushes are one of THE most important tools to have when tuning and waxing skis and snowboards, and without them you simply cannot obtain the best results from waxing your skis or board. But why so many wax brush choices? And what has a drill got to do with things? Let me show you how to choose the right waxing and structuring brush, and why you may need more than one. For those typing into google “ski waxing brush order” read on…

What is a wax and structure brush for?

From our ski tech training courses, it is often the case that people do not know what part brushes play in ski and snowboard tuning and waxing. Brushes serve two purposes for us when waxing skis and snowboards; We can open the base structure before we wax, and they add structure and expose base structure after waxing. To explain, if you were to get a sheet of smooth glass, run a bath of water and place it on top, you would have a hard time pulling it from the surface. This is because the two smooth surfaces are sticking together thanks to a “capillary force” created by two smooth surfaces being placed together, and not wanting to part in a hurry. Now imagine the glass is your ski or snowboard base, and the water is the snow on the ground. We need to “break” that stiction, and we do it by adding channels down the length of the ski from tip to tail, which break up the surface releasing the tension. This is called Base Structure. We have a machine here that can add structure to a base, but these cost around £20K so discounting that, we can use brushes to put a structure into the base, and also after waxing to expose that structure. Doing this, the snow droplets glide down our structure like ball-bearings, allowing the ski or snowboard to glide better, and not stick. So get your wax choice right, and add in a structure, and you will significantly improve the performance of your skis or snowboard.

What do the different types of brush hairs do on the brushes you sell?

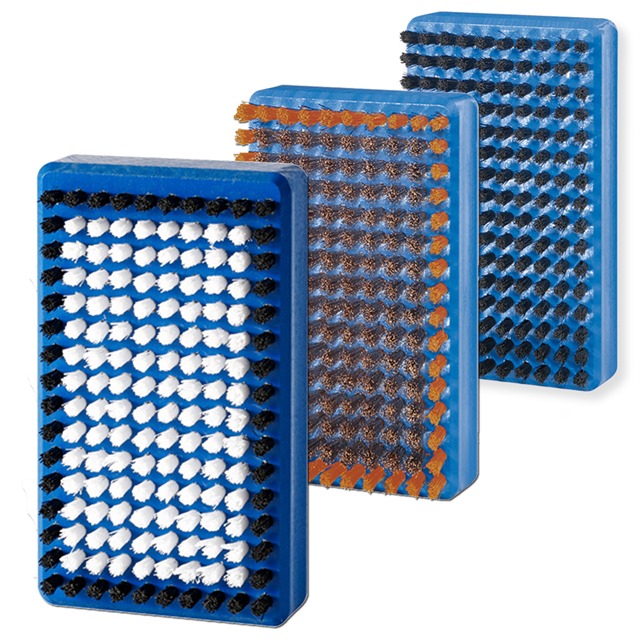

our new 3 brush value kit gives you Scott’s 3 favourite brushes

Each of the brush hair materials are designed to do different things. Some are a “workshop essential” and some are for racers or those wanting to tinker with their skis and snowboards to get improved performance.

Nylon Wax Brushes

Scott’s Ratings: Pre waxing Structure: 6/10, Post waxing Structure: 6/10, Polishing: 6/10

These are the benchmark brushes, if you can only afford one brush THIS is it. A nylon brush is durable, medium-hard stiffness, and can be uses to brush structure into bases before waxing AND for polishing wax after its applied and cooled, to expose base structure for improved glide. It is great with universal and medium and soft waxes. IF its really wet conditions, where the snow will be globby and slushy, a more aggressive brush will help, but for 99% of occasions the nylon brush is ideal.

view nylon brushes

Horsehair Brushes

Scott’s Ratings: Pre waxing Structure: 4/10, Post waxing Structure: 6/10, Polishing: 9/10

The horsehair bristles on these brushes are more numerous and finer than a nylon brush, resulting in a different structure to nylon. Ideal on medium and harder waxes, it adds additional structure although does not penetrate as deep as a nylon or brass brush. It is our go-to mid-temperature wax brush, and we will combine the horsehair with the nylon to give a great all-round structure. Horsehair is best at polishing wax to reveal structure after waxing, not so good for opening structure before waxing.

view horse hair brushes

Brass/Bronze/Copper Brushes

Scott’s Ratings: Pre waxing Structure: 9/10, Post waxing Structure: 5/10, Polishing: 3/10

The brass brushes are very effective at opening up base structure, but are often bought in error, as people assume more money equals a better brush. The brass brush is best for creating base structures before waxing. It can be too aggressive for opening structure up after waxing except if using a hard or cold conditions wax, where they will penetrate the wax more effectively.

view copper/brass brushes

Steel Wire Brushes

Scott’s Ratings: Pre waxing Structure: 10/10, Post waxing Structure: 2/10, Polishing: N/A

These brushes are for expert use, and those valuing performance over base life. Steel brushes are available with different wire brushes and will create and expose structure very easily on bases. In wet snow conditions or thawing temperatures, racers will have a very open and exposed structure on their ski bases, to deal with the more globby nature of the snow surface and combine this with softer waxes. However, for us mere mortals, steel structuring does take life away from bases, so it is to be used with caution and where performance is key.

view steel wire brushes

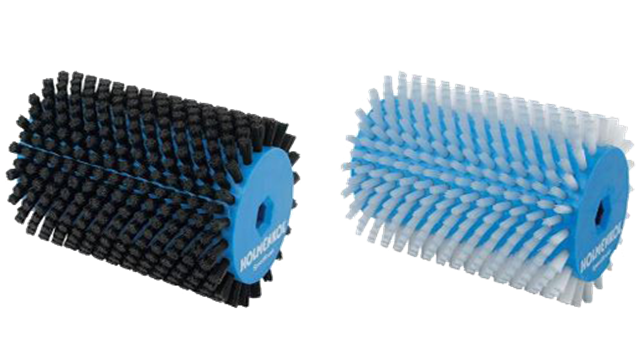

Why do you sell rectangular brushes and oval brushes?

We offer two shapes on most of our brush options. The smaller rectangular shaped brushes are the width of “traditional” skis, and for the home DIY tuner. The oval style offers a more secure grip thanks to the build in handle, and covers a wider surface area ideal for snowboards and wider skis. The hairs on oval brushes are often longer too, making them more durable and faster for professional workshop use.

So if you are tuning your skis and snowboard once in a while the rectangle versions are fine, and the oval version will be faster to work with, more durable and a little safer thanks to the strap handle.

Are rotary ski and snowboard wax brushes any good?

Yes! If you are tuning regularly, they are a huge timesaver and offer more consistent results. I still remember the first day I moved from handheld brushes to a drill version. They are incredibly efficient. These work by being mounted on a dedicated brush axle, inserted into a cordless or electric drill. The brush can then be passed down the ski to expose structure and do very high levels of polishing for professional results. Available in two widths for skis or snowboards, the snowboard version is a revelation on brushing snowboards which takes a long time – and can be used on skis too.

If you are going to be servicing regularly, and have a good drill – as they take a beating using a rotary brush – then these are a fantastic upgrade and available in all types of hair, and also fleece and cork options for the most amazing polishing results too.

view our rotary brush and axle range

How do I care for my tuning brushes?

The normal method that shoe polishing brush owners use of soapy water offers poor results, as the wax will resist the water. We regularly clean our brushes using a non-solvent cleaner like Holmenkol Wax ab or alcohol, soaking the brush and then using to brushes against each other to brush out old wax and dust, and leave them to dry. The key thing is to be careful where you leave your brushes when finished with them so they do not get contaminated, and ideally base side facing the worktop.

If you want to find out more here is a video I made when at Edge & Wax about the Holmenkol wax brush range:

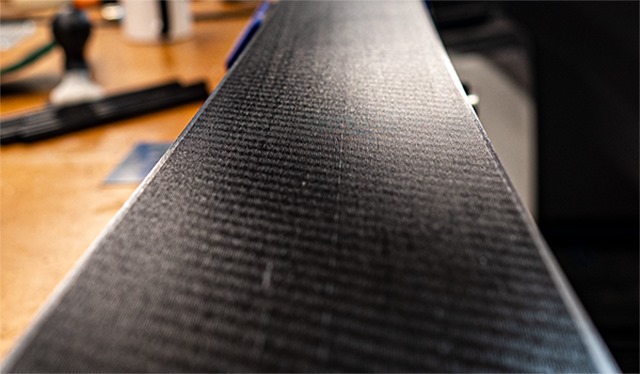

When you have completed a proper waxing and brushes of your ski bases, with a bit of luck they can look like this example from our workshop…

Need more advice? Just get in touch with us.